Mastering the Embroidery Digitizing Process: Your Ultimate Overview

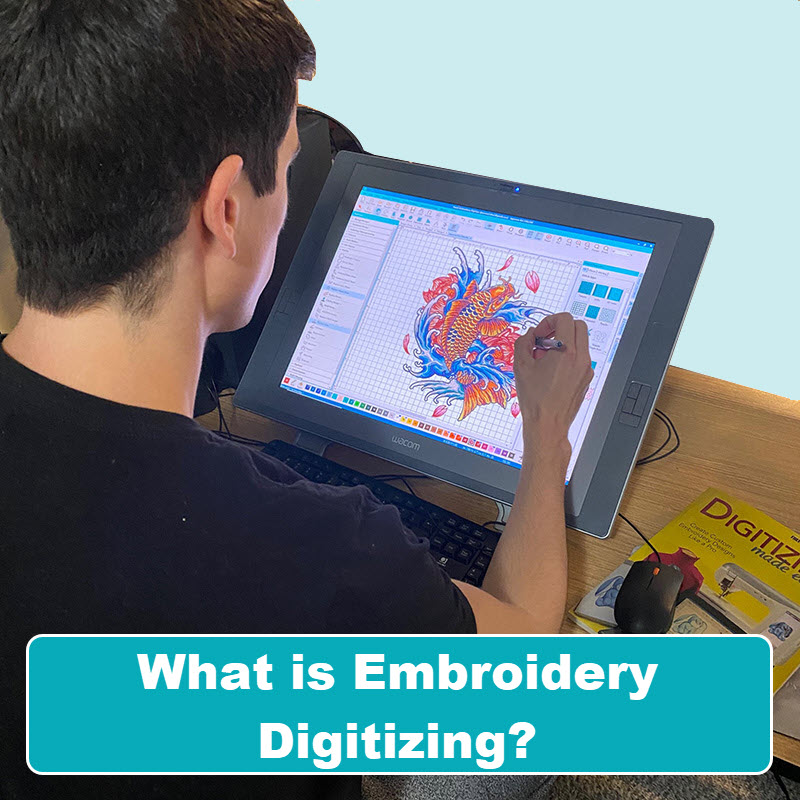

Embroidery digitizing is a meticulous craft that requires precision and proficiency to equate detailed layouts into electronic formats for equipment needlework. As artisans get started on this journey to grasp the needlework digitizing procedure, a thorough understanding of the fundamentals establishes the structure for excellence.

Comprehending Embroidery Digitizing Basics

Needlework digitizing fundamentals form the structure whereupon complex designs are converted right into machine-readable formats for specific sewing. This first action in the needlework digitizing procedure is essential for making sure that the final embroidered product is a loyal representation of the original layout. Comprehending needlework digitizing essentials includes understanding crucial principles such as stitch kinds, stitch direction, thickness, rug, and pull payment.

Stitch types play an important role in determining the visual and textural outcome of the stitched style. By picking the suitable stitch kind, whether it be satin, fill, or running stitch, digitizers can achieve the wanted effect and improve the total quality of the needlework. Furthermore, stitch direction affects the flow and measurement of the design, while density establishes the spacing and insurance coverage of the stitches.

Additionally, padding sewing gives security to the design by protecting the fabric and protecting against distortion during the needlework procedure. Draw settlement is another vital factor to consider to combat the natural tendency of material to contract when sewn. Grasping these needlework digitizing essentials is fundamental for producing professional-quality stitched products.

Selecting the Right Digitizing Software Program

Picking the suitable digitizing software program is an essential choice that considerably affects the efficiency and top quality of the needlework digitizing process. Digitizing for Embroidery. When selecting the appropriate digitizing software, it is necessary to take into consideration factors such as the intricacy of layouts you plan to develop, the user-friendliness of the software application, the level of consumer support supplied, and the compatibility with your embroidery equipment

There are various digitizing software application alternatives offered in the market, ranging from basic programs for newbies to innovative software application for expert digitizers. Some prominent options include Wilcom EmbroideryStudio, Hatch Needlework Software Program, and PulseID. These software program packages supply a large range of devices and functions to help you develop complex layouts easily.

Before making a choice, it is a good idea to explore the various software choices with cost-free tests or trials to establish which one finest suits your demands. Furthermore, reviewing reviews and looking for suggestions from skilled digitizers can offer useful insights into the strengths and weak points of each software (Digitizing for Embroidery). By meticulously evaluating your requirements and contrasting the functions of various digitizing software program, you can make an informed selection that enhances your embroidery digitizing operations

Digitizing Devices and Strategies

Optimizing Style Settings for Needlework

Understanding the complexities of layout setups is basic in attaining optimal cause the embroidery digitizing procedure, structure upon the structure laid by comprehending digitizing devices and techniques. When maximizing design setups for embroidery, it is necessary to consider aspects such as stitch kind, density, underlay, draw compensation, and enrollment. Stitch kind choice influences the general feel and look of the Clicking Here style, with alternatives like satin, fill, and running stitches providing different textures and results. Density refers to the spacing and thickness of stitches, impacting the layout's protection and toughness. Correct rug stitching gives stability and avoids material distortion, particularly for intricate styles or on stretchy products. Draw compensation readjusts for textile stretch throughout sewing, making sure exact style duplication. Registration setups align various elements of the style accurately, preserving general layout stability. By fine-tuning these design setups, embroiderers can enhance the high quality and accuracy of their stitched developments.

Troubleshooting Common Digitizing Issues

When experiencing typical digitizing concerns during the needlework process, it is crucial to understand the source and execute reliable solutions without delay. One usual trouble is stitch thickness concerns, where stitches might be too thick, creating the textile to pucker, or too click this thin, bring about spaces in the design. Adjusting the stitch density setups in the digitizing software can help settle this concern.

Another regular difficulty is thread breaks during the needlework procedure. This can occur as a result of different reasons such as incorrect tension settings, plain needles, or using low-quality thread. Ensuring appropriate maintenance of the needlework equipment, including regular needle changes and tension modifications, can lessen the event of string breaks.

Moreover, design registration errors can lead to misaligned aspects within the needlework layout. Checking the design alignment in the digitizing software application and making needed modifications prior to sewing can assist in preventing this concern. By resolving these usual digitizing issues quickly and properly, you can guarantee a smoother embroidery process and high-grade ended up items.

Verdict

Finally, understanding the embroidery digitizing process calls for a strong understanding of the basics, the ideal selection of software application, and expertise of devices and techniques. Enhancing style settings and repairing usual digitizing issues are essential action in making websites sure top quality embroidery results. By adhering to these steps faithfully, one can attain precision and effectiveness in the digitizing procedure.